Welcome! This is the third in the Concrete and Wood Geometric Collection, a series of four furniture builds brought to you by Jen Woodhouse and myself. In case you missed them, we previously introduced this bookshelf, and this dining table. Today’s build is this coffee table, and check out that base! The base on the coffee table is different than the dining table in that it is formed with half lap joinery. I love half laps because they look fantastic, and they are really quite accessible.

As with the rest of the pieces in this collection, the plans are at jenwoodhouse.com, and I’ve got a tutorial and build tips here for you. (And a video!)

Here’s an idea of what you will need for this build:

Materials

2 3/4 x 2 3/4″ lumber

Concrete

rebar mesh mat

4×8 sheet 3/4″ melamine

3/8 ” wood dowels

wood glue

Tools:

miter saw

table saw

dado stack

drill

9 mm drill bit

clamps

Here’s a quick video overview of the coffee table build:

Build the coffee table:

Step 1:

Mill your chosen wood to 2 ¾” square. You can use reclaimed or fresh lumber. I used reclaimed and cut down all sides for a clean look.

If you use reclaimed be sure to plan where each piece will go in the design so that the desired faces are showing. That can be a bit more tricky with salvaged wood.

Step 2:

Cut wood to approximate sizes – l like to leave them an inch or two long while I’m still planning and determining layout. Once you have determined where each piece will fit, cut the miters. Keep pieces laid out so you don’t mistakenly cut a miter the wrong direction.

Step 3:

Cut the half laps. Start by marking out the location of each of the half laps.

This is also a great time to double check that the joints are all lining up right by lining up opposite boards, as shown:

Half lap set up:

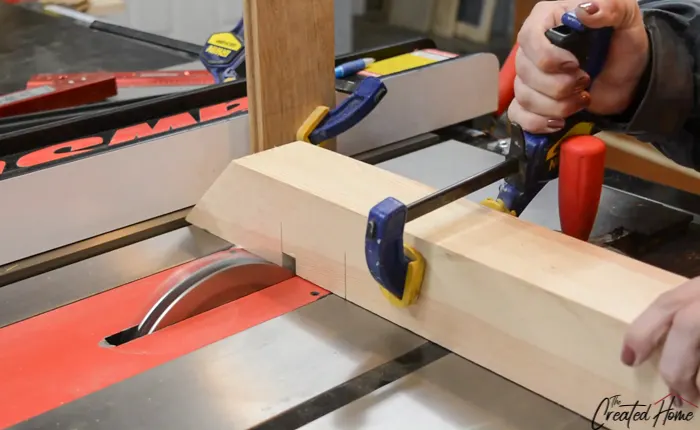

The video shows how to do this far better than I can describe this, so if you missed that scroll back up and watch. My chosen method for half laps is a table saw with a dado stack. You can cut with a regular blade, but you will have to make 5 trillion cuts instead of like 5…or something like that. Set the height of the blade to half the thickness of your wood.

Next, set up the wood for the cut. The simplest way to set it up is to clamp your piece of wood to the miter gauge. I set a terrible example here and didn’t use a sacrificial piece of wood, which just means that you first screw a piece of wood to the miter gauge, then clamp your piece of wood to be joined to it. That way when you make the cut it won’t tear out at the back because the backer – or sacrificial – piece prevents that from happening.

Why didn’t I do it that time? I really don’t know. Do as I say, not as I do.

Carefully line the blade up with one side of the line, make sure the piece is clamped securely, turn on the saw, and run the piece through. I like to use the clamps as handles, as shown in the video. Stop the saw, move the piece over, and run it through again. When you get to the opposite side don’t go right up to the line. Sneak up on it slowly over a series of cuts, fitting with the other board (the one you are joining to) each time so you can get a good, snug fit.

Step 4:

Seal the end grain before gluing the miters. As in the other builds in this collection, I used a 50-50 mixture of glue and water.

Step 5:

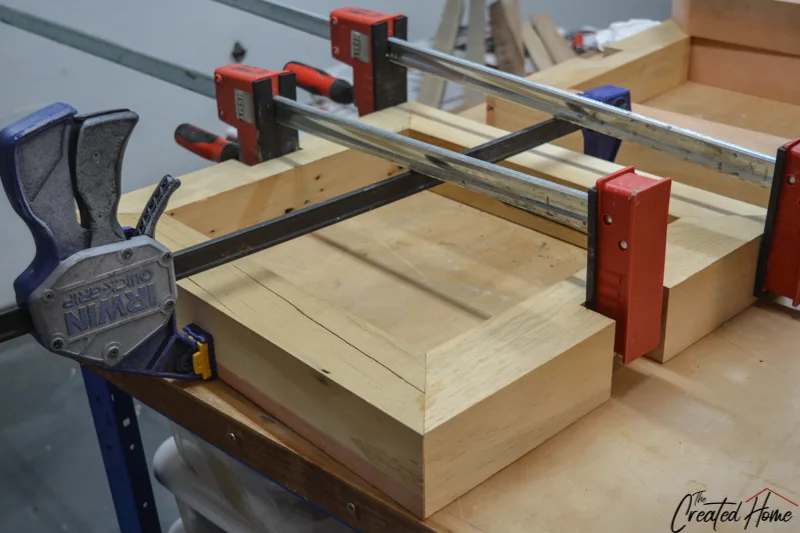

Glue up the miters a couple at a time, being sure not to glue so many joints that you cannot put the table together. Just make sure everything will go together as you go. My preference is to wait 24 hours before reinforcing any with pegs – which means this step has to be done in shifts and takes some time. Again, be sure to leave a side or two open as needed (aka – don’t complete the squares) so that you can assemble it. You will end up gluing and clamping the last couple miters in place, during assembly.

Step 6:

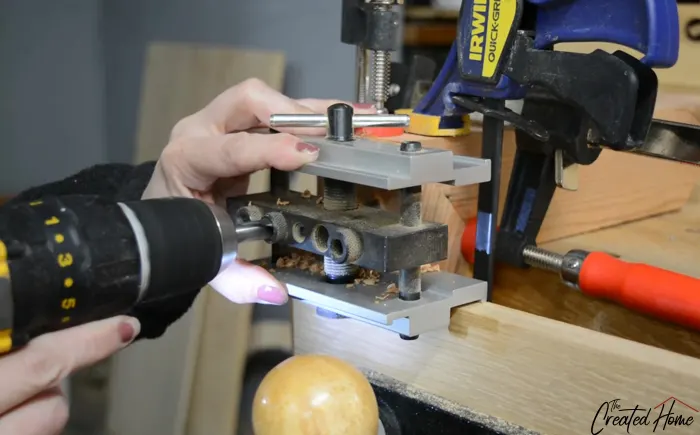

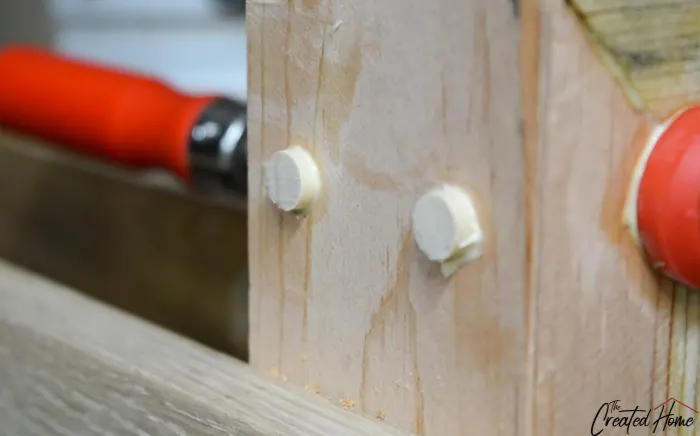

As in the other parts of this collection, I chose to use dowels or pegs to join the mitered corners. I like this method because it is simple and very effective. I use a doweling jig to start a hole through one miter into another, running the hole maybe 2 inches or so. Due to the size of the wood the jig couldn’t sit over the wood, so I left it on the surface and was able to at least get each hole started straight.

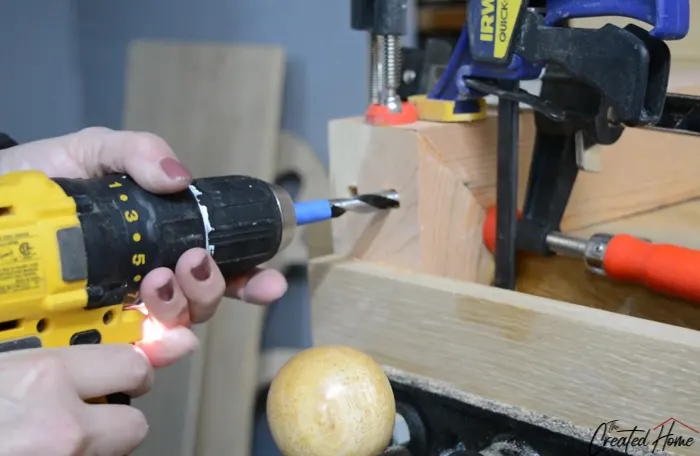

That was enough to then drill by hand. I used a brad point bit for this, at either 3/8″ or 9mm. I switched dowels mid way through and realized that they were not precisely the same size. One fit best with a 3/8″ dowel, and one with a 9mm. Those a reallllly similar sizes, but you want the tightest fit possible, so check this with the dowels you use.

I dropped glue in each hole, then glued in a 3/8 dowel. I like to cut mine a bit long, then use a flush cut saw to cut off the ends.

Work through the pieces and sections a couple at a time, clamping and setting as you go. I keep the sections in clamps while drilling and tapping in the pegs because it can be rough on those end grain glue ups.

Step 7:

Assemble the table, gluing and clamping sections that go together at this point.

Step 8:

Sand. I wait until this step because things tend to get roughed up a bit in process, but you could smooth some earlier if desired.

Step 9:

Attach the concrete top. I’ll give information about making concrete furniture tops in a separate post.

Step 10/Tip:

This table is NOT LIGHT. Emphasis there. To protect the floors it is a good idea to add felt or some sort of slider feet to the bottom. Actually, you should probably do that before adding the concrete…

That’s all there is to it. What do you think? Do you like the half lap, interlocking design of this table, or do you prefer the square-in-square design of the dining table? Be sure to check back in for the final piece in our Concrete and Wood Geometric Collection this week, and then for a DIY concrete tutorial soon after!

How To Make A DIY Geometric Concrete and Wood Coffee Table

Wednesday 15th of April 2020

[…] new piece in the Geometric Collection! I collaborated with incredible and talented Sarah from The Created Home on this furniture collection and have been loving every piece so far! The concrete and wood combo […]

MINA HARLEY

Wednesday 30th of October 2019

I like this design of yours, very specific and informative article, I have saved this article and made a reference for myself. Thank you very much.

Sarah

Tuesday 16th of June 2020

Thanks!

MINA HARLEY

Wednesday 30th of October 2019

great