Building this wood beam round dining table with plans designed by my friend Jen Woodhouse is basically a heavens-opened-angels-singing dream come true.

I mean…

You can pick up the free plans for this table from Jen’s site here. And I just have to add that if you are not already following her on Facebook and Instagram you are totally missing out. She has plans for a ton of gorgeous pieces on her site, and she’s a crazy talented builder and designer as well as one of the nicest people you’ll ever meet.

I would define this as more of an intermediate build, and to that end I’m going to go over a few options for how this thing can be crafted. You can build this table out of fresh lumber or reclaimed – it will look great both ways. Personally, I love to build with reclaimed wood, so the beam legs are reclaimed barn wood. That necessitated a change in measurements from the plans, given the salvage beams are true 4x4s instead of the 3.5″ boards you get with new lumber. Other changes include using half-laps for the base and adding an extra border. Basically what you’ll need to do is to skip sections that go into an option you don’t want to do.

The top is constructed using 2x4s from Home Depot. I ran the boards through my planer first to eliminate the rounded edges and make the mosaic pieces sit tightly together. If you do not have a planer you can achieve the same result with a table saw. Just be sure that each piece is dimensionally identical. (Dimensionally may or may not be a word.)

Ignore the dinosaur on the boards. I have kids.

You are probably catching on that this will be a bit of a more detailed tutorial. I’m including several videos as well. I want this to be as helpful as possible, and if you have any questions, please ask!

Okay, let’s get building!

*This post includes affiliate links for your convenience. Check out my policy about that here.

Tools and Materials

The tools and materials are listed in the plan PDF you can download from Jen’s site, but I’ll include a few links here to some of it so it is easy to find.

Figure 8 table top fasteners

9/16″ Forstner bit (for the fasteners)

Plunge router (this is a great one if you are just getting into router work)

Kreg Trak and Stop System (This isn’t essential, per se, but I consider it invaluable)

Parallel clamps (for clamping the mosaic top for assembly. I use these inexpensive ones from Irwin, though you’ll want to get the 48″ clamps from Lowes rather than online)

Pipe clamps (this is the assembly for the galvanized pipe. They are essential if you are planning to add the extra round border)

Planer (okay, this isn’t a small one, but if you are going to dive in, I cannot recommend this one highly enough)

Belt sander

Orbital sander

Weatherwood Stain

Weatherwood Conversion Varnish

Round Dining Table Base

Again, you can use fresh 4×4’s or reclaimed for the table base. I choose reclaimed for the base and fresh for the top, then used an aging stain to match the top to the base. More on that later. I bring it up here because if you want an aged look without using reclaimed wood you could also use an aging stain. I use Weatherwood Stains, which I’ll discuss later.

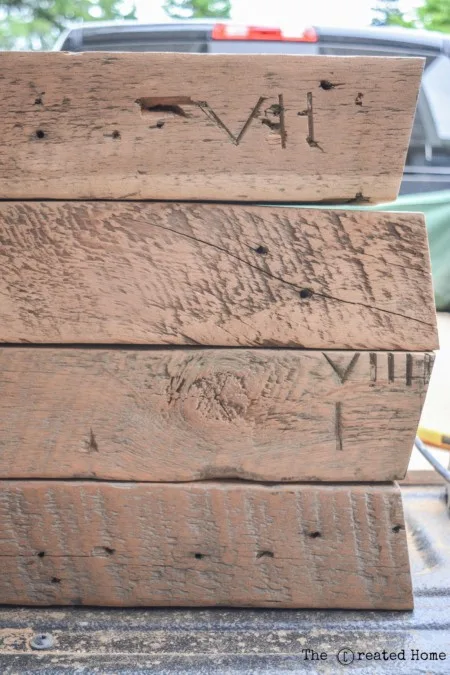

Selecting and Cleaning Reclaimed Lumber

I purchase my reclaimed lumber from a salvage wood business that also kiln dries their materials. I was lucky enough to find this amazing pine wood from a barn in western Oregon. The roman numerals are part of a system where barn builders would match adjoining beams by number. How cool is that?!

That patina is amazing, but they are also very dirty. So I put them through the paces. Quick rough sand with 80 grit, scrub down with water and a touch of dish soap, dry, then sand again with 120, and finalize with 220. This process retains the texture, but leaves a smooth, clean, and splinter free surface.

After cleaning:

Cutting the frame

The legs are cut at 10 degree angles with the ends parallel to each other.

The lower cross pieces are also cut at a 10 degree angle. Fit it as you go to be sure your cuts are going the correct direction. I rested each leg up against the ends and made a pencil mark showing the direction of the angle cut. Better safe than sorry.

The cross pieces on top are cut at 90 degrees. Here’s a look at how it fits together. I used a 2″ high piece of wood as a spacer under the bottom while dry fitting, since that’s the height I wanted to use for the final assembly.

Here’s where I made another minor change. You can skip over this next section entirely if you prefer to join the cross pieces with pocket holes.

Cutting the half lap joints

Here’s a look at how the base cross pieces were going to fit together. You’ll want to mark center, then cut lines on either side where the boards will fit together. My boards were 4″, so I chose to cut to 2″ depth on both boards.

I’m sure there are several methods for cutting half laps. I use a table saw. A circular saw would also be a great, and probably safer method since half laps can be dangerous. (Mine is beveling and needs to be replaced, which is why I didn’t use it.) A cross cut sled is a great option. I cut the outside, lines, then take a ton of cuts out of the space in between. Then I use a chisel to clean out the material.

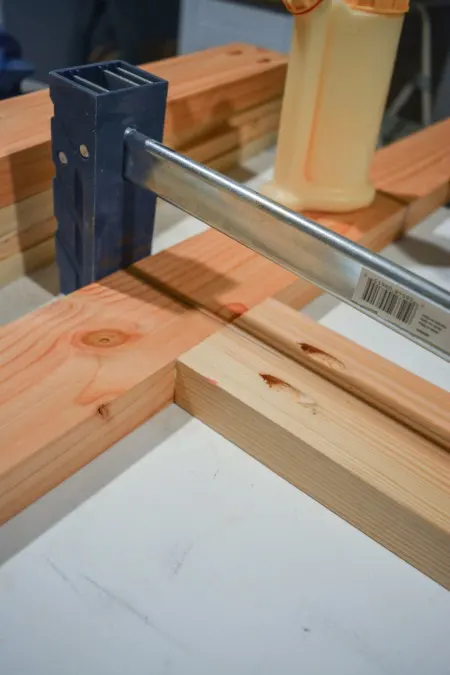

I glued the pieces together and let them sit for a day or so before moving on.

Joining the base pieces

Next, I leveled in the base cross piece and marked a line on the legs where the bottom of the cross pieces met up with each leg.

I used the block piece from my Kreg Jig and lined it up with the line I made in the last step. You can clamp the piece to the legs or screw it down (there is a spot for it). I went with screwing it down because it was easy. Drill 1 1/2″ holes 2″ up from the bottom.

This part was tricky. Attach the cross piece to the legs with 2 1/2″ pocket hole screws. Ya, it may have been more of a two person job. Two people or 40 clamps, I don’t know. Use glue, find a way to hold it all together, and attach them. Good luck.

Side note: You may notice that the cross pieces don’t fit together level on the bottom. I used wood with slightly different dimensions, so that happened. It’s flush on the top, so it’s fine, but in hindsight I would rather use equally dimensioned pieces.

It does get easier after that first leg…

There it is with the legs all attached. If this were a cooking show I would say “At this point you should have something roughly resembling a Star Wars X Wing. Congratulations.”

Tip the X Wing over and check level. Okay, hopefully you are reading ahead before doing the next step, because I’m going to toss something else your way. I actually made two of these tables, a 48″ and a 60″ version. You can see both table bases in the next photo. The first gave me such fits with the clamping and pocket holing that I tried another way with the larger table base. I glued the living daylights out of it where the cross piece meets the legs, then put clamps with just a little pressure on it in place. I left it that way for a few days, because I strongly believe in overkill. I was able to gently lift the table and add the screws after that. That’s probably my preferred method, at least with a base that large.

Are you still with me? The top cross piece is pretty simple. Simply glue it to the top, assure reveal is the same all around, then countersink 4″ screws into the legs through the top. This piece will be covered by the table top.

Whew! The base is finished! And it looks aaaaamazing. You’re half way there. I promise the next part is shorter.

Actually, that’s a total lie. But it does include more videos, so there’s that. Onward!

Round Dining Table Top

I joined the top cross piece with pocket holes and glue.

You’ll need to cut the triangle pieces to fit precisely. We cut and fit each size at a time. Use a lot of glue. Copious amounts of it.

As promised, a video. Here’s a look at the process I used.

There are a bunch of options for putting the mosaic table top together. You could use pocket holes, screws, pegs, biscuits, or floating tenons (dominos). Use what you have and what you are comfortable with. I used a pretty simple method, and it worked great.

Tip: I worked from the underside of the table, but in hindsight I would flip it over and work from the top. That would help with the top board alignment and make for less sanding on the top.

You will want to leave the screws out of the final two sections entirely. Glue, clamp, and screw if you like, but then remove the screws before adding the next board. If you are not planning to add a final extra border you will need to stay away from adding screws to the final board. Screws left in those last couple rows will be in the way of the router.

There it is!

In a perfect world your top will fit together perfectly smooth. I am not that good, so we used a belt sander to smooth it out, top and bottom.

We only belt sanded it at this point, finish sanding will be later.

Cutting the top

There are circle cutting jigs on the market, but you can get the same result with a piece of wood. Screw one end to the center of the table bottom, then mark your desired radius on the other end.

Basic round cut router jig

Let’s talk a bit more about that jig. Ours was simply a 5″ or so wide board with a a screw at one end for attaching to the center (bottom) of the table. The other end has a hole that matches the diameter of the bit we are using. We used a 1/2″ bit for this cut, though a 3/4″ would have been just fine as well. Be sure that your hole is on the outside of the line so you don’t cut too short. You’ll need to attach your router to the board. Configurations differ by router, of course, but you’ll want to get the screws that hold the router to the plate attached to the board.

Tip: You’ll want to use a spiral upcut bit rather than a straight bit to cut the round. Spiral bits are meant for cross grain cuts, so they prevent tear out.

Here we go!

I know some woodworkers cut off the extra material with a jig saw before using the router. Whichever way you go, be sure to take small amounts of material at a time.

You are done!!!! Unless you want to add the extra border. Which is crazy. Don’t bother. Save your sanity. Be done, put some finish on that beautiful thing, and enjoy your new table. Just skip this next section and jump to the finishing section…

Adding the extra round border (optional)

If you are reading this you are crazy. I respect that. Okay, really, the extra border is a gorgeous addition, and I personally have no regrets for the extra time it took. And, lucky you, we went through this and have a few pointers to make it easier for you.

Make a jig for the inner curve

Study the photo. Here’s what’s going on. We attached the same circle cutting jig that we used to cut the table round to a 2×4, which is in turn attached to a piece of scrap plywood. You’ll want to use 2x8s for the border, and sandwich them firmly between a couple more 2x4s. We used 2×6 boards, and ended up having to cut 9 instead of 8. (This was for the larger version of the table.) Had we used 2×8 boards we would have been able to cover the circumference with 8 pieces, which would have been better.

Whichever size you used, make sure it’s tight in place between the 2x4s, and that you screw another piece to the end so the piece cannot slip out the end. Now you’ll be able to run the router across each board in an arch that matches your table round.

Tip: Be sure the center of the board is dead center on your jig so the arch is the same on each board. In other words, you want the center of the arch (the highest point) to line up to the center of the board it is on.

Here is what that process looks like:

I’m light on photos here, so bear with me. You’ll want to mark out equal pie shapes on the table. Take the number of pieces you’ll have on the outside and divide it by 360. So for our nine outside pieces we had 40 degrees for each section of the pie. If we had done 8 we would have needed 45 degree slices. We drew right on the table, which needed sanding, anyway. We then held each piece up to the table and extended the lines onto the board. That gave us our cut lines. Notice in the photo below that I also tacked scrap boards to the bottom of the table so the pieces we were adding could rest there while we measured and figured it out.

We measured, marked, and cut in groups of three. We then used the Kreg Jig to pocket hole the pieces to each other, being sure to stay out of the path of the final round cut. Then we glued the ever loving crap out of it (the photo is not a good representation) and clamp the ever loving crap out of it.

Pipe clamps were the only way to go here, because there were gaps that we had to squeeze out. We left those clamps on for a day or so, and the result is a border that is very strong and secure. Guys, I hung on them.

Now you are simply going to cut out another circle. Only bigger. That does necessitate yet another jig. You don’t necessarily have to clear the grooves like we do in the video. I’ll be perfectly honest, my router motor is going out. So sad.

Tip: It may seem obvious, but sometimes when you are in the middle of the things obvious isn’t necessarily obvious. So a reminder: make your cut from the bottom of the table, else you will have a hole at the top. Also, have a partner for this stuff. It’s not a solo thing, and you’ll need someone to remove the cut pieces so they don’t tear out as they come off.

Finishing your table

Oh my gosh, you are here at last. All your hard work has paid off and you have a gorgeous table to share with family and friends. All you need to do now is attach that table top and finish it how you like.

Attaching the table top

This was my first time using figure 8 fasteners, and I was pleased. They are simple to work with and install quickly. Here’s a quick look at the process.

You’ll want to leave enough of the 8 hanging off the side so it can move. The fasteners allow for wood movement, meaning your table won’t tear itself to shreds as the seasons change and the wood shifts.

As I mentioned before, I used 2x4s from Home Depot to create the top, and reclaimed barn wood beams for the base. I used aging stain to match the top to the bottom, and the match was utter and complete perfection. Like, angelic choirs singing hallelujah perfect. That good.

My stain of choice is Weatherwood Stains. I have tried a good number of aging stains, and simply put, it works the best. It is not the cheapest on the market, but the cost is well justified by how well it works, in my opinion. Let’s talk perspective for a moment: If you are replicating a $2500 Restoration Hardware table for maybe a couple hundred dollars, a good, quality finish is worth every penny of the investment. It takes a small amount of stain to do a project like this, and there is enough stain leftover for me to think about aging everything I can get my hands on. Ya, I do that.

Here’s a final pre-stain view:

For this table I used Reclamation Stain. Pining stain is a better choice for low tannin woods like pine, but Reclamation happened to match, well, perfectly. We covered that. I finished the table with Weatherwood Dead Flat Conversion Varnish. That’s the same varnish I have on my own dining table, and it is not only incredibly matte, it’s stood up to my toddlers like a champ. Case in point, I recently discovered marker on the table. I was able to wipe the marker way with a wet rag and some elbow grease. Bam. Just like that. (Few things warm a mom’s heart more than kid resistant furniture.)

Enough talk. You probably didn’t even read that, did you? This is the fun part. Oxidizing stain isn’t meant to be wiped away. Just put it on and let it soak in. Like magic.

Okay, time lapse magic. That took about 25 minutes. And here it is!

I love how natural the stain looks.

And how well does that pair with the base?!

All that’s left to do is take a final few longing looks at the finished table before getting to work on your own. Because you know you have to build one.

That was a ton of information. I hope it was helpful. Again, I’m happy to help if you have any questions. It was such an honor to get to build this with Jen. This definitely goes down as one of my favorite designs, from that beam base to the mosaic top. Don’t forget to grab the plans and check out Jen’s other beautiful work!

Happy Building!

Restoration Hardware Inspired Dining Table – Sweet Home Savvy

Thursday 15th of October 2020

[…] looked easy enough, and I came across these great plans to build it from Sarah at The Created home with pretty detailed step by step […]

DIY Wood Beam Round Dining Table

Wednesday 27th of May 2020

[…] She made a few modifications to the table – she added the curved perimeter, for example – which is no easy task. I didn’t include this in the plans because I wanted to keep them as simple and straight-forward as possible. However, Sarah goes into great detail in her tutorial, so be sure to check that out if you want to i… […]

How to work with reclaimed wood - The Created Home

Sunday 16th of February 2020

[…] The results are this dining table: […]

jenny

Saturday 25th of January 2020

Love this table top!!!! Please tell me how long did you cut your 2x8s for the addition to the tabletop.....

Sarah

Sunday 1st of March 2020

Ugh, this is slightly painful for me to see. Honestly, with a bit more experience under my belt I probably wouldn't do it that way at all anymore. The easier method would probably be to create an octagon shape (or however many sides it needs) using straight pieces of lumber, then lay the inner circle (the main part of the table top) on top of it and trace the circle. Then you would only have to use a jigsaw to cut out the template you made. I searched around and found Modern Builds doing that method here if you want to check it out: http://www.modernbuilds.com/diy-round-farmhouse-dining-table.

The short answer is that I'm not sure what the lengths were. Probably around 18". But like I said, I wouldn't go that route again. I hope that helps!

Jill House

Tuesday 20th of August 2019

How would you modify this if you wanted to make the table bigger? Like 72”

Sarah

Monday 23rd of September 2019

You'll need to build the middle cross section longer than the total of 72", then fill in the quadrants. You can do all of the mathematical work on it, and I don't know that off the top of my head, but I can tell you that you'll need to go longer than you total desired diameter because when you cut the round you will loose some of the radius. I hope that makes sense. I believe Jen has the measurements for two sizes of the table on her site, so that can help you see how the lengths of wood had to change to get that larger diameter.