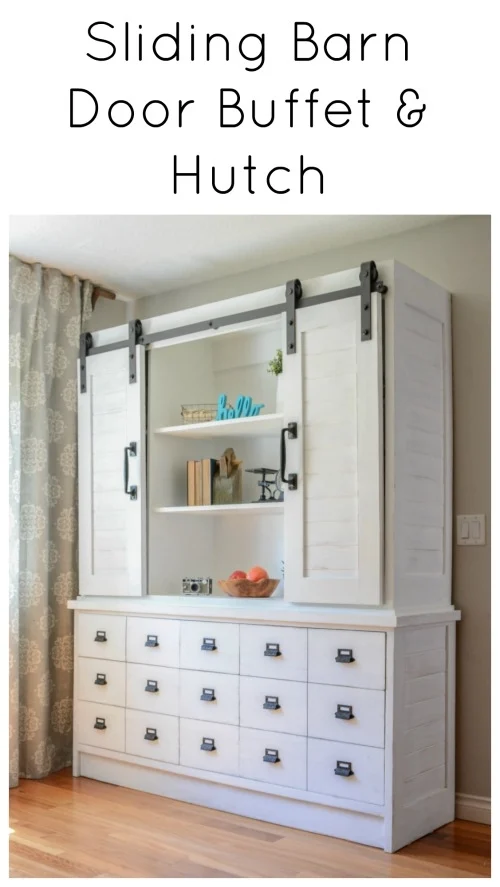

Are you ready to add some shiplap glam to your life? I’ve paired up with the always amazing Jen Woodhouse to bring you this shiptastic farmhouse buffet and hutch.

*This is a sponsored post, but all opinions are my own.*

If you haven’t already done so, you’ll want to check out the buffet plans here and tutorial here.

The hutch plans are available on jenwoodhouse.com. Jen and I also teamed up with Purebond® Plywood to bring you the plans and tutorial. Guys, I use Purebond® for pretty well all of my builds that don’t include reclaimed wood…and some that do, come to think of it. Between the two, that roughly totals roughly 100% of what I build. I love the high quality of the plywood, which I have used on everything from my workbenches and tool stands in the shop to my kids’ lego table to my living room fireplace and built ins. You can find them at any Home Depot and…drumroll, they will even ship it to your door, like I had them do with the gorgeous walnut ply for the top of the fretwork table also designed by Jen. And here’s a tip for you: If cutting it seems intimidating you can totally have them do it for you. Whaa?!

Okay, so let’s get down to building this big beauty! This is part two of a two part tutorial. The Hutch.

*This post contains affiliate links. You can learn more about what that means here.

Materials

2 – 1x2x8

3 – 1x4x8

3 – 1x3x8

1 sliding hardware bar

Extra sliding hardware hanger set

1 – 1x6x8

1 – 1x8x8

¼” ply 2 – 4’x8’

2 – ½ x ¾ x 8

1 – ½” Purebond® Plywood 4’x8’

2 – ¾” Purebond® Plywood 4×8

1 ¼” brad nails

½” brad nails

1 1/4″ pocket hole screws

Wood glue

2 handles

V-groove planks – 1 pack

Finishing supplies: dependent on your method of choice:

stain

bondo

paint

stain

Tools

Miter saw

brad nailer (I have and totally recommend the Airstrike by Ryobi)

drill

table saw and/or circular saw (I’ve included a couple links to what I use and love)

Kreg Pocket Hole Jig

Kreg Trak and Stop System (totally optional, but believe me, you’ll be happy you have it when it comes to all of those shiplap planks)

stain

The Hutch

The sides of the hutch are constructed in the same manner as the buffet, but with 1x4s. Use glue and brad nails to attach the rails and stiles to the plywood.

(PS. In the summer the back of my truck doubles as a third workbench. Because if there is one thing I know to be true about life, it is that there is no such thing as too many workbenches.)

Cut the v-groove planks to length so they are a snug fit, and dry fit them before gluing. I had a gap of about a half inch left at the end. Glue and while the glue is still wet spread the planks apart until they fit the gap. There should be enough room to not have gaps due to the tongue.

All glued up! I did not use any nails on the v-groove planks.

Pocket hole and attach the ends to the bottom on a flat surface so it all comes out even. A 3/4″ support under the base will eliminate sagging.

At this point I moved the hutch carcass to the ground because it’s huge. Check it out next to the in-process buffet.

The middle supports should be 3/4″ short of the sides to allow for the top. Use the rails from the next step as spacers to ensure everything is even and attach with pocket holes.

I choose to stain the piece before painting so that dark wood would should through when I distressed it a bit, so at this point I went ahead and started staining. There’s a lot of pieces to get to and I find it helpful to do it as I work while everything is a little more accessible.

Next I cut the shelving. I also cut spacers so they would all sit evenly. So, here’s where there’s a bit of a quandary. I attached the shelves with pocket holes on the bottom. Because that’s what you do. Right? Righhhht, so this is a hutch on top of a buffet. You guessed it, those holes all showed like a beer belly in a bikini. Doh. If I built this one again I would pocket hole the tops of the upper shelves and the bottoms of the lower shelves, then fill them with plugs or Bondo.

Attach the 1×8 header to the top.

Tip: When you attach the sliding barn door hardware the screws will show on the other side. Because they are made for walls and stuff. I realized this too late in the game to change it up, but it is easily solvable by adding another layer behind that header first. Those pieces would have to be attached like the back with pocket holes.

Build the doors like the sides with more Purebond® Plywood, 1x4s, and v-groove boards.

This seems like a good time to share another tip. When plywood and board are butted up, as in the sides of the doors, you can hide the seam with a bit of Bondo. I mix it up, apply a good, liberal layer, then sand it back. This only works if painting, however, as the bondo does not stain.

All painted up! The good folks at House of Antique Hardware sent these gorgeous cast aluminum door pulls that are pretty well everything. Seriously, as good as they look here, they are even better in person. They go with the pulls on the buffet, which are also at House of Antique Hardware, like a freaking dream.

Time for the barn door hardware! The bar will have to be cut down to fit the hutch. The bolt holes will likely fall right over that end seam, which doesn’t give a ton of room. We cut ours a bit too short, so I would recommend cutting them so they pretty well extend to the edge of the hutch. You will want as much space as you can get between that final bolt and the end of the bar. You’ll see why in a moment.

As far as the cutting, we used an old miter saw blade that we keep for such purposes. Whatever method you use, be sure to take proper safety measures. No one wants a piece of metal in their eye, right?

File the cut ends lightly so they are not razor sharp. I touched up the cut ends with some matte black paint and you would never know they are cut. We penciled in where the drill holes would be, drilled all the holes, then attached the outside first without over tightening. We did the middle two next, then went back and attached the outside bolts.

Hang the doors according to manufacturer instructions. Leave about a 1/4″ gap between the top of the door and the slider bar when you lay it out. Remember how I said to leave the bar a little ways from that end bolt? That extra space will allow you to attach the stop so the doors cannot be pushed off the bar. I do this first so you get the benefit of not making all of my mistakes.

The final step is to cut and attach your 1/2″ x 3/4″ wood trim to the base of the hutch. I did this step last because I wanted the hutch on top of the buffet first. It is attached with brad nails to the hutch, so that piece can still be lifted off the buffet, but it looks seamless because it was placed snug up against the base, if that makes any sense.

I finished it up in place – a little paint touch up here, a bit of sanding there, and we caulked the seams inside the shelving area to really make it nice and clean. And there you have it! Check out this eye candy!

I love it so much. I confess that it is a bit too large for my space (insert heartbreak and agony here). But there are rumors of a slightly smaller version of the buffet and hutch in the works. In the mean time, let’s get lost in how gorgeous this hutch is, shall we?

Barn doors, shiplap, and storage for dayyyyys. Sigh!

If you love it, pin it up and make it happen! Happy building!

*Thank you so much to the good people at Purebond® Plywood for partnering with us on this project!

Best Shiplap Cabinet Doors Design Ideas - aliceopera

Monday 26th of October 2020

[…] sliding barn door hutch created home cabinet doors. source […]

Jason Myopic

Sunday 1st of March 2020

Great project! It is unusual to see a barn door used in furniture, but I like it!

Sarah

Tuesday 16th of June 2020

Thank you! It's a unique detail for sure.

Rude69

Saturday 29th of February 2020

I was recommended this blog by means of my cousin. I'm no longer sure whether or not this put up is written by way of him as nobody else understand such distinct about my difficulty. You're amazing! Thank you!

Rebecca | Confessions of Parenting

Monday 14th of January 2019

This is beautiful! I love the look of the barn doors. Absolutely stunning

Sarah

Wednesday 30th of January 2019

Thank you! It was a fun piece to build. :)

Angie overton

Sunday 29th of October 2017

Oh how I love this! Just found your page. Off to go see what else you have here. Thanks for sharing!

Sarah

Thursday 23rd of November 2017

Thank you, Angie!